What is a Stirling Engine?

A Stirling engine is a type of heat engine that converts heat into mechanical work using a fixed amount of gas inside the engine.

Here's a simple breakdown:

- Heat Source: The engine is heated from an external source.

Working Gas: Inside the engine, a gas (like air or helium) expands when heated and contracts when cooled.

Pistons and Cylinders: The engine has pistons and cylinders that move as the gas expands and contracts.

Cycle: The engine works in a cycle:

Heating: The gas heats up, expands, and pushes a piston.

Cooling: The gas cools down, contracts, and pulls the piston back.

This cycle repeats, driving the pistons to produce mechanical work.

Key Points: External Combustion: Heat comes from outside the engine. Efficiency: Can be very efficient, especially with a good heat source and regenerator (a component that reuses heat). Versatility: Can run on any heat source, including solar, geothermal, and fossil fuels. Overall, a Stirling engine is a quiet, efficient engine that works by heating and cooling a gas in a continuous cycle.About the Stirling Engine

A Stirling engine is a type of heat engine that operates by cyclically compressing and expanding air or other gas (the working fluid) at different temperatures, thereby converting thermal energy into mechanical work. Named after its inventor, Reverend Robert Stirling, who patented it in 1816, this engine is notable for its high efficiency compared to steam engines of the time and its ability to operate on any heat source.

Basic Principles and Components

1. Closed-cycle operation:

Closed Cycle: The working fluid remains inside the engine, allowing it to be continuously reused. Working Fluid: Typically air, hydrogen, or helium is used due to their favorable properties such as thermal conductivity and specific heat capacity.2. Regenerative Heat Exchange:

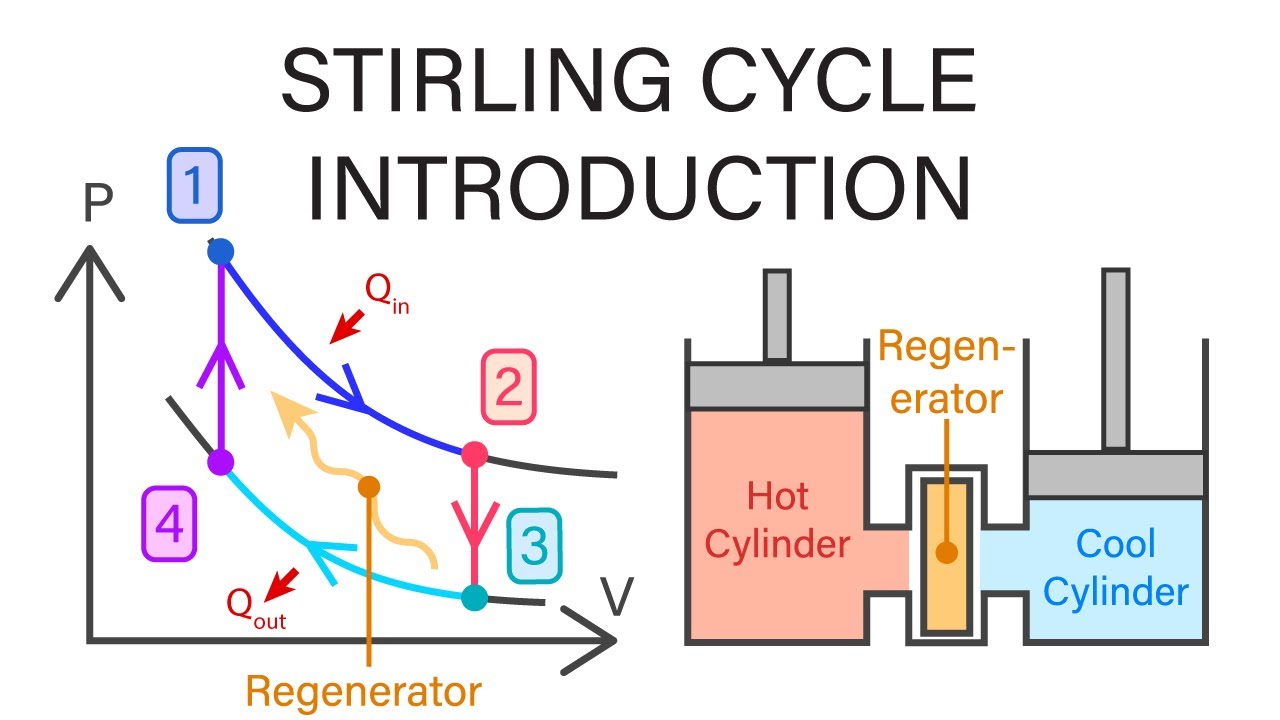

Regenerator: A crucial component that temporarily stores heat from the working fluid during one part of the cycle and returns it to the fluid during another part, greatly improving efficiency.3. Four Phases of Operation:

Expansion: The working fluid is heated, causing it to expand and push the piston. Transfer: The fluid moves to a cooler area of the engine. Compression: The cooled fluid is compressed by the piston. Return: The fluid returns to the hot area to restart the cycle.

Types of Stirling Engines

1. Alpha Type:

Comprises two separate pistons: a hot piston and a cold piston, located in separate cylinders. The hot piston is exposed to the heat source while the cold piston is exposed to the cooling source.2. Beta Type:

Features a single power piston and a displacer piston in the same cylinder. The displacer piston moves the working fluid between the hot and cold regions without performing work itself.

3. Gamma Type:

Similar to the Beta type but with separate cylinders for the power piston and the displacer piston. Allows for more compact designs.Operation Cycle

The Stirling engine's operation is typically divided into four key processes:Heating: The working fluid absorbs heat from the external heat source, causing it to expand. This expansion pushes the piston and does work.

Displacement: The displacer piston moves the working fluid to the cold side of the engine.

Cooling: The working fluid releases heat to the cooling source, contracting and reducing its pressure.

Compression: The cooled, contracted fluid is compressed by the power piston, completing the cycle and allowing the process to begin anew.

Applications

Stirling engines are versatile and can be used in various applications such as:

Renewable Energy Systems: Solar power generation, where the engine is driven by concentrated solar heat.

Marine Engines: Utilizing waste heat from ship engines.

Domestic and Industrial Heating: Combined heat and power (CHP) systems where electricity and heat are produced simultaneously.

Cryogenic Cooling: Reverse Stirling engines can act as refrigerators for cryogenic applications.

Advantages

Fuel Flexibility: Can run on any heat source, including solar, geothermal, biomass, and fossil fuels.

Efficiency: High thermal efficiency due to the regenerative heat exchange process.

Quiet Operation: Fewer moving parts and external combustion result in quieter operation compared to internal combustion engines.

Disadvantages

Size and Weight: Typically larger and heavier than equivalent power internal combustion engines.

Cost: Higher initial cost due to complexity and precision required in manufacturing.

Power Density: Lower power-to-weight ratio compared to internal combustion engines.